Getting gas distribution right is non-negotiable in any lab—whether you’re running chemical experiments, analyzing samples, developing new drugs, or teaching the next generation of scientists. Solid gas piping design means steady gas flow, fewer leaks, and a safer workplace for everyone. Knowing the standards is the first step to building a system that’s both reliable and safe for the long haul.

Core Safety Principles for Lab Gas Piping

Lab gas piping has to meet tough standards. The materials matter, the pressure controls need to be spot-on, and everything has to resist corrosion. Installation isn’t just about putting pipes together—it’s about following practices that keep things running safely day in and day out. These systems handle nitrogen, hydrogen, oxygen, argon, helium, high-purity gases, and plenty of other specialty gases, so there’s no room for shortcuts.

Choosing the Right Piping Materials

Your choice of pipe really decides how safe and durable your setup is. Stainless steel—especially EP and BA grades—works best for high-purity gases and stands up to corrosion. Copper pipes with a protective coating can handle some inert gases. If you’re moving corrosive or reactive gases, go for PTFE, PVDF, or lined pipes. Pick the right material, and you’re already ahead on safety and performance.

Installation Requirements You Can’t Skip

To meet lab safety standards, you need solid installation. That means orbital welding or high-quality TIG welding for joints that won’t leak. Keep fittings and bends to a minimum—every extra turn just drops your pressure. Route pipes away from heat and electricity. Label everything clearly: what gas is inside, which way it’s flowing, and the pressure zones. Strong brackets keep the pipes steady and safe.

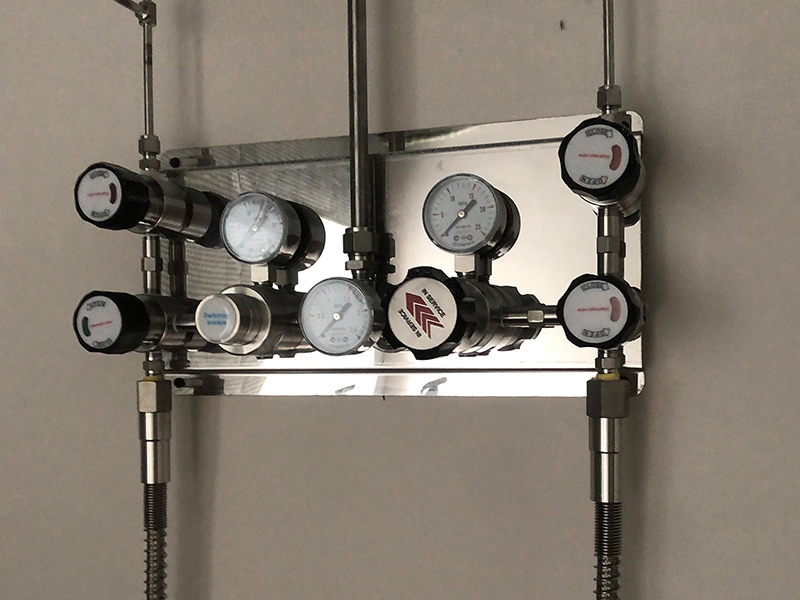

Locking in Gas Pressure Control

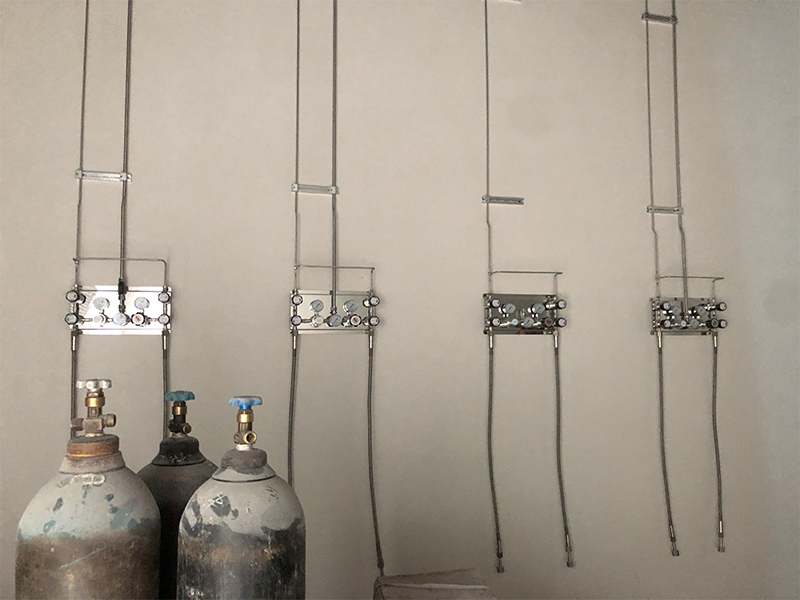

Consistent pressure keeps your tools accurate and your lab safe. Most labs run with two-stage pressure control: the main regulation happens at the gas cylinder room, then you fine-tune it near the instruments. This setup keeps the output pressure steady and shields your sensitive equipment from pressure spikes.

Staying Ahead of Leaks

Preventing gas leaks is one of the most important jobs in any lab. Every system needs thorough testing—think helium leak detection or pressure-holding tests. Safety valves and backflow preventers are a must. Gas detection sensors should cover everything from hydrogen and oxygen deficiency to combustible and toxic gases. For extra protection, use automated shut-off valves and ventilation interlocks.

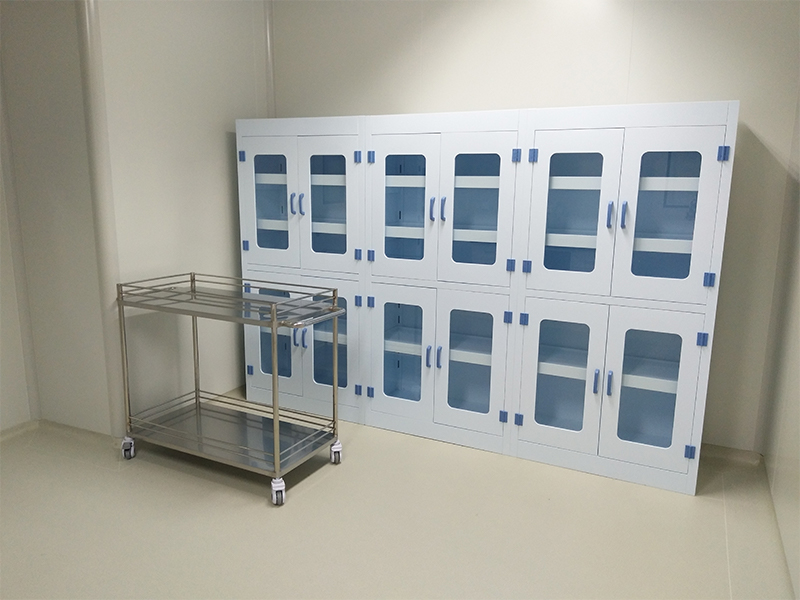

Managing Gas Manifolds and Switching Systems

If your lab uses multiple gas cylinders, a manifold system keeps the gas supply seamless. Manual switching works fine in low-use areas. For bigger setups, automatic switching means you can swap cylinders without losing pressure or interrupting your work. High-purity labs often rely on fully enclosed manifolds with purge systems to keep things clean.

Routine Testing and Maintenance

Regular checks keep your system running smoothly. Inspect joints, valves, regulators, and sensors. Track pressure readings and catch wear-and-tear early. Keep clear records for every maintenance check and safety audit—it’s not just about compliance, it’s about peace of mind.

When you design your gas piping system with the right standards, you protect your experiments, your team, and your reputation. Stick to these rules, and you’ll keep your lab’s gas distribution stable, clean, and up to code—no compromises.

Brought to you by huajusheng Lab Equipment—your partner for specialized lab gas piping systems, centralized gas distribution, and complete lab engineering support.