Let’s be real—gas pipelines in a lab are kinda like the quiet kid in class: you barely notice them till something goes wrong, and then, boom, everyone’s paying attention. If a leak pops up, it’s not just annoying—it can get seriously dangerous, fast. We’re talking fire, explosions, nasty fumes. The whole nine yards. So, yeah, finding leaks before they get wild is non-negotiable.

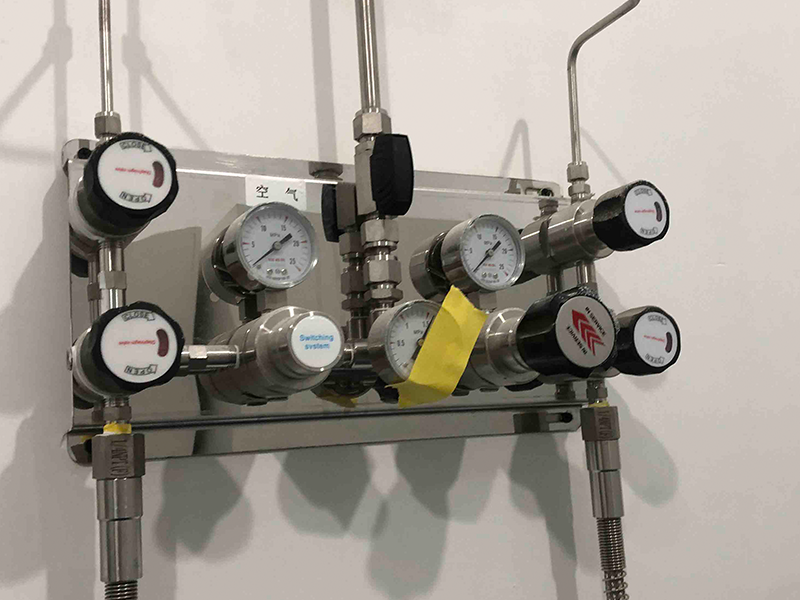

How do you even spot a leak? Honestly, it starts with a good ol’ eyeball check. Poke around the valves, joints, and connectors—anywhere the pipeline’s got a weak spot. Most modern labs have fancy gas detectors with real-time sensors. Those things are lifesavers (literally). But don’t underestimate the classics: pressure-drop tests still work, and the soap-solution trick? Bubbles don’t lie. Oh, and don’t ignore weird smells, hissing noises, or if your equipment starts acting possessed. If something feels off, it probably is.

Now, say you think there’s a leak—what’s next? Don’t go full action hero. First thing, cut off the gas at the main valve. No gas, no problem, right? Then, get everyone out. Seriously, don’t try to be a hero. Hit the ventilation to clear out whatever’s floating around. Once everyone’s safe, call in the pros—the emergency team or fire department. Labs should always have clear exits, fire extinguishers that aren’t just for show, and safety manuals that aren’t collecting dust.

Bottom line: A solid plan for pipeline maintenance and emergencies doesn’t just save your boss’s wallet—it keeps everyone in one piece. Spend a little on smart monitors and make safety training a regular thing. It’s way better than explaining to your supervisor why the lab smells like a gas station, trust me.