Let’s be honest—lab gas pipelines aren’t exactly glamorous, but mess them up and you’ll wish you hadn’t. These pipes are the lifelines for labs. You want your gases delivered, not leaking out somewhere they shouldn’t be. Skipping maintenance? That’s basically asking for leaks, nasty contamination, or even a full-on “call the fire department” situation.

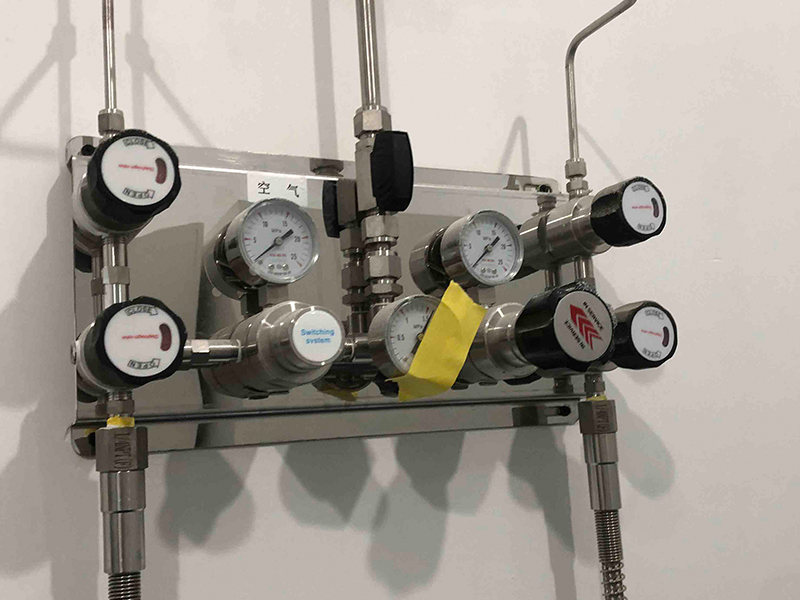

So, first off, don’t just hope everything’s fine—actually look. Regular inspections are a must. You gotta check for rust, cracks, loose bits. Don’t just eyeball the pipes, either. Valves, regulators, all those tiny connectors—they need love too. If something feels off, fix it before it becomes a thing. Waiting for a disaster is… well… a terrible plan.

Leaks—yeah, those are the real party crashers. Get yourself some pressure tests, throw in gas sensors, set up alarms. If something starts escaping, you want to know about it yesterday. And hey, don’t forget about airflow—good ventilation is non-negotiable. You don’t want to walk into a room full of invisible danger, right?

Swapping out old parts before they fail? That’s just smart. Gaskets, seals, tubing—replace them regularly. Don’t cheap out, either. Stick to certified materials and follow whatever the manufacturers say, even if it’s a pain. Trust me, it’ll save headaches (and cash) down the line.

Oh, and people—your team. If they don’t know how to handle gases safely, you’re basically rolling dice every day. Train everyone. Emergency shut-offs, safe handling, the whole deal. It’s not just for the new folks, either—everyone needs a refresher now and then.

Last thing—paperwork. Yeah, it sucks, but you need it. Keep records of every inspection, repair, upgrade… all of it. If the safety inspector shows up, you’ll be glad you did. Plus, if anything goes wrong, you’ll have a breadcrumb trail to follow.

Bottom line: look after your gas pipelines and they’ll look after you. Skip the drama, keep things safe, and your lab will run like a dream (or at least not explode).