If you run a lab in Johannesburg—whether it’s a research institute, a mining lab, or a chemical analysis facility—solid chemical control in your ventilation system isn’t just nice to have, it’s non-negotiable. With all the hazardous substances floating around, proper ventilation keeps your people safe, stops cross-contamination in its tracks, and keeps you on the right side of South African safety laws.

It all starts with a solid fume hood. Labs dealing with acids, solvents, or anything volatile need a fume hood that holds a steady face velocity, usually about 0.45 m/s. That’s what actually grabs and traps dangerous vapors before they start causing trouble. In places where people are always working—think busy Johannesburg labs—Variable Air Volume (VAV) systems do the heavy lifting. They don’t just blast air at a constant rate; they adjust airflow on the fly, so you get both safety and energy savings.

Then there’s airflow zoning, which matters a lot in mining and metallurgical labs scattered around Johannesburg. You need chemical handling zones to stay under negative pressure so fumes don’t drift into clean rooms or instrument areas, which usually run at neutral or even positive pressure.

Filtration can’t be an afterthought. If your lab deals with heavy metals, VOCs, or corrosive gases, you’ll want serious filtration—HEPA, activated carbon, maybe chemical scrubbers. These keep your exhaust air clean and make sure you’re not polluting the neighborhood, which is a real concern in crowded research hubs like Braamfontein or Randburg.

Don’t underestimate the impact of good monitoring. Sensors that track VOC levels, airflow velocity, pressure, and filter saturation give you a heads-up if something’s off. Modern labs tie this data right into their building management systems for remote monitoring—super useful if you’re running a multi-floor operation.

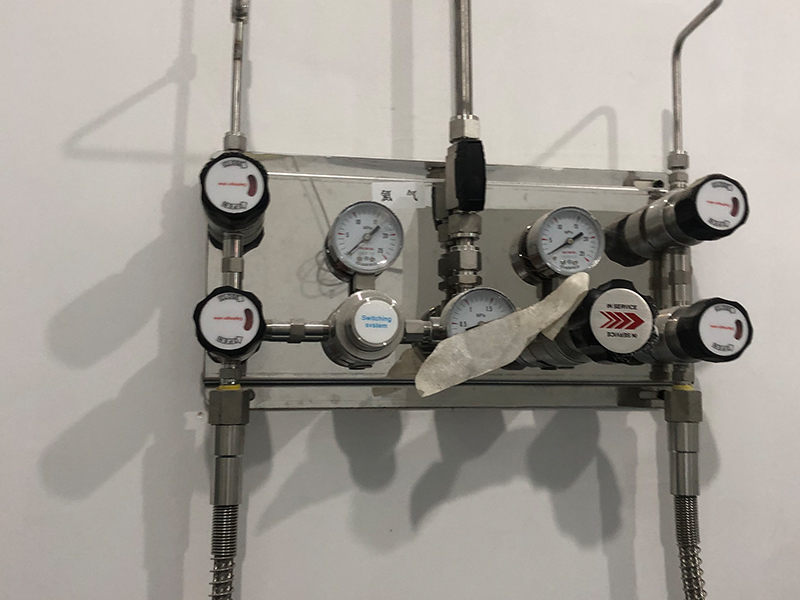

Emergency controls are a must. You need automatic shut-off valves, exhaust systems that kick into high gear when alarms go off, and special ventilation modes for spills. These features matter, especially in industrial labs experimenting with flammable or oxidizing chemicals.

Maintenance keeps it all running. Duct cleaning, filter swaps, recalibrating airflow, and checking your sensors—these jobs make sure your system stands up to Johannesburg’s dusty, sometimes harsh environment.

Put all this together—engineered airflow, pressure zoning, tough filtration, smart sensors, and emergency automation—and you’ve got a lab that stays safe and steady, even when you’re working with some of the nastiest chemicals out there.