Alright, picture this: you’re in a lab, and you’ve got gases under serious pressure zipping through a maze of pipes. Not exactly the time to cut corners, right? The whole system’s gotta be bulletproof—one tiny leak and boom, you’re on the evening news for all the wrong reasons.

First up, material choice. Don’t mess around here. Stainless steel is basically the gold standard—tough as nails and laughs in the face of corrosion. Sometimes you’ll see copper with protective coatings, but only if the pressure isn’t nuts and the rules say it’s cool. Don’t just grab whatever’s lying around.

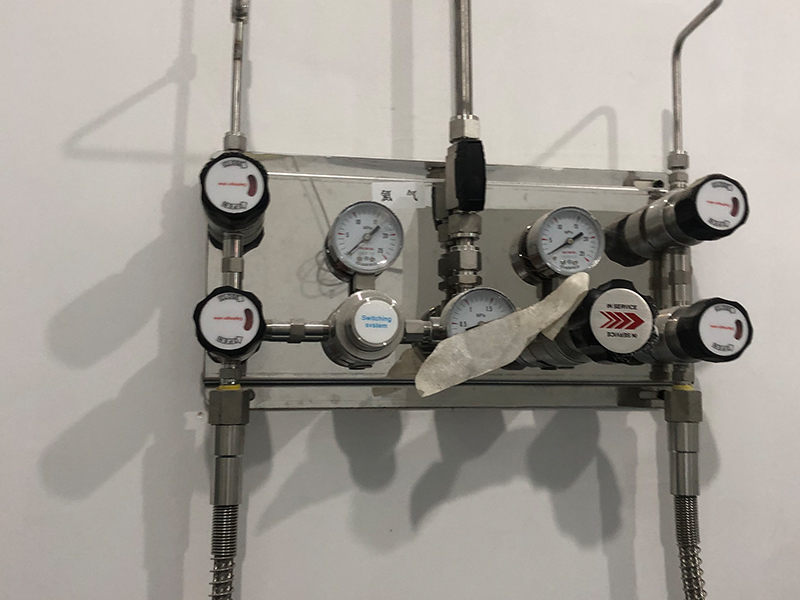

Layout matters too. Keep those pipes as straight as you can—every twist and turn is a chance for things to go sideways (and for pressure to drop). Regulators and relief valves? Non-negotiable. And for the love of science, get someone who actually knows what they’re doing to weld those joints. No DIY energy here.

Now, let’s talk brains: monitoring and control. Pressure sensors, auto shut-off valves, all that fancy tech. If something starts to go sideways, you want alarms blaring and valves slamming shut before you even know there’s a problem. Bonus points if your system talks to your lab management software—compliance is a pain, but you’ve gotta play by the rules.

Maintenance is your unsung hero. Schedule regular pressure tests and leak checks, swap out valves before they’re ancient, and don’t let your team wing it in emergencies. Drills, training—the whole nine yards.

Bottom line? High-pressure gas piping in labs is serious business. It’s not just about sticking some metal together. You need killer materials, rock-solid standards, smart tech, and a crew that knows what’s up. Nail all that, and your lab runs smooth, safe, and maybe even a little bit badass.